The company’s headquarters is at the Bois-de-Villers site and houses the administrative departments, a factory covering 5,000m² where the fireplaces are assembled, and a factory showroom covering 1,300m² presenting Stûv products.

The site is equipped with solar panels that produce a good proportion of the electricity used, helping to reduce its environmental footprint.

Stûv applies the principles of lean manufacturing in order to avoid any form of waste and guarantee on-going improvement, including in particular by relying on Quick Response Management.

The Floreffe site includes the Research & Development department, which is made up of a design office, an in-house laboratory and a production workshop.

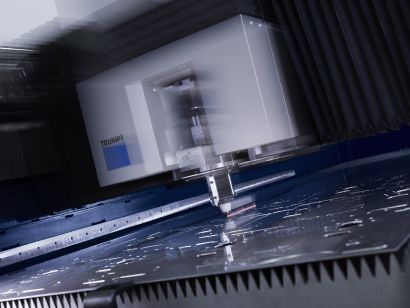

This workshop, equipped with advanced equipment used to produce one-off pieces limited edition runs, makes prototypes and manufactures the range of finishes. Electrostatic coating equipment helps to extend the range of finishes available.

In 2016, Stûv acquired ULIS Design, a company specialising in designing and producing precision metal parts.

This factory, based in Thuin, produces some of the sheet metal components for Stûv fires.

Based in Canada, near Montreal, the Bromont factory assembles fireplaces for the North America market (Canada and the United States).

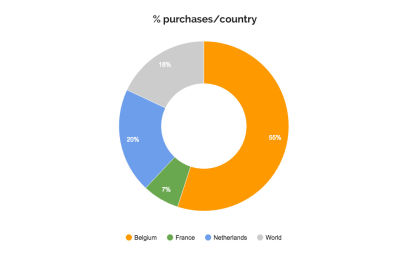

A Stûv stove or insert contains a large number of components. For each one of these components, Stûv looks for the best experts, mainly in Belgium, the Netherlands and France.

Assembly takes place in the Namur region for Europe, and in Bromont near Montreal (Canada) for North America.